Product Sheet Configurations Get a Quote

The EasyTube® 2000 is an advanced turnkey thermal chemical vapor deposition system for the synthesis of a wide variety of thin films and nanomaterials.

The base system can process 50 mm x 50 mm diameter substrates and has a 3-zone resistance heated furnace. The system is optimized for controlled process development and user safety. Our modular platform includes a range of options which can be configured to meet your specific processing requirements. Many of the options are available as upgrades after installation.

The system is designed to meet today’s safety standards for handling pyrophoric, corrosive, flammable, and toxic gases such as hydrogen, silane, germane, diborane, hydrogen chloride, and metal organic precursors. The system has application configured safety protocols embedded into relay logic, PLC, and CVDWinPrC™ software.

FirstNano® offers turnkey system capabilities with support equipment such as gas cabinets and exhaust gas conditioning systems. All major components from one vendor makes interfacing easy. The FirstNano® EasyGas™ gas cabinets are capable of delivering a variety of toxic and hazardous gases. The EasyExhaust™ system will thermally pyrolyze and wet scrub the process effluents.

STANDARD FEATURES

- CVDWinPrC™ system control software for realtime process control, data logging, and recipe editing

- Preprogrammed process recipes

- Substrate sizes up to 50 mm x 50 mm

- Cantilevered automatic substrate loading/unloading system

- Up to 8 mass flow-controlled UHP gas lines

- Atmospheric and/or low pressure process configurations available

- 3-zone resistance furnace for temperatures up to 1200 °C or optional rapid thermal processing with infrared heater

- Proprietary realtime cascade process temperature control

- High throughput with FastCool™ furnace

- User ability to set warnings and alarms

- Comprehensive software and hardware safety interlocks

- 1 year warranty

- On-site system startup and training

- Semi - S2/S8 and CE Compliant

OPTIONS

- High temperature resistance furnace up to > 1200 °C

- Infrared heating for rapid thermal processing > 1100 °C

- DC bias field-assisted growth

- Rectangular process tube for improved laminar gas flow

- Up to an additional 4 mass flow-controlled UHP gas lines

- Liquid/solid source vapor delivery kit

- Bubbler liquid auto refill

- Run/vent: stabilizes gas flows (bypassing the process tube) before flowing into process tube

- Residual gas analyzer

- Air to water heat exchanger for cooling water

- SDC® hazardous gas cabinets

- SDC® UHP gas panels for argon, nitrogen, helium, oxygen

- CVD exhaust gas conditioning system (scrubber/pyrolyzer)

FACILITY REQUIREMENTS

Electrical

208 VAC

60 Hz | 30 - 40 Amps

L1, L2, L3, N, G

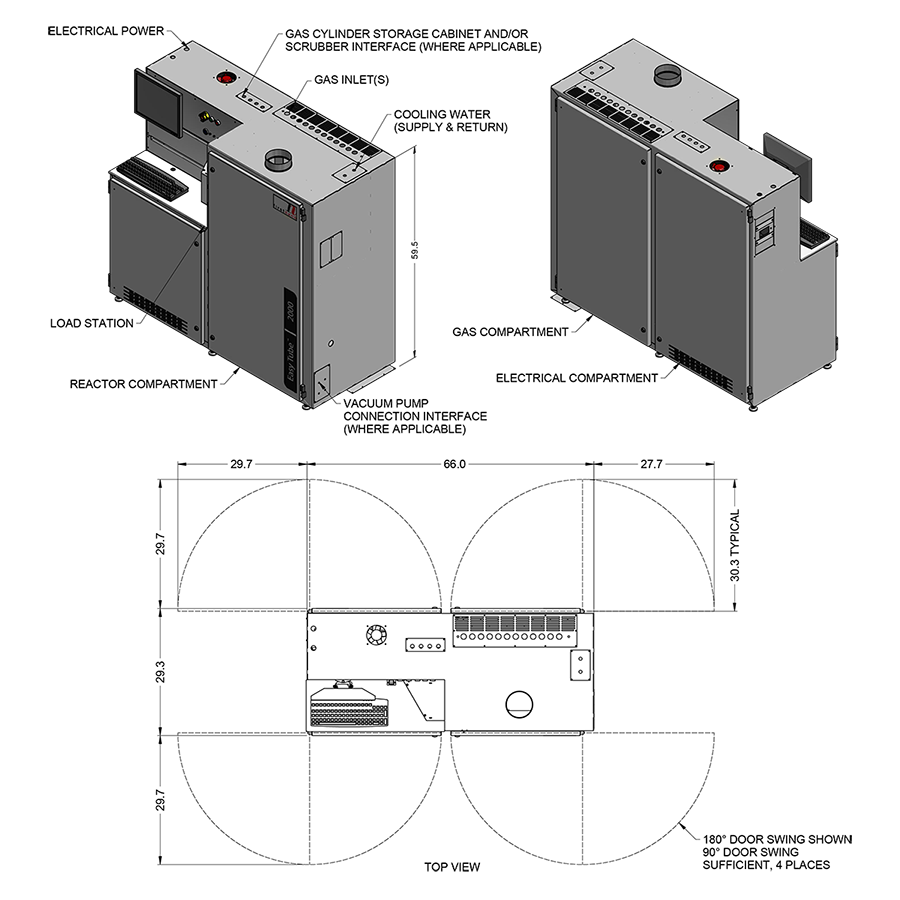

Dimensions

64" Length

30" Width

60" Height

Cabinet Exhaust

300 SCFM

1" WC

N

Facility Nitrogen

10 SLM

20 PSIG

Pneumatic Supply

1 SCFM

80 PSIG

Clean Dry Air or N2

Process Gases

Customer Specified

Electrical varies with country | Facility requirements vary with system options | Consult Factory for details